In today's highly competitive alcoholic beverage market, for enterprises that are dedicated to building beverage brands, having good anti-counterfeiting labels on products is extremely crucial. On one hand, it can effectively prevent counterfeit and shoddy products from emerging and strongly protect the rights and interests of consumers. On the other hand, for the brand itself, products with anti-counterfeiting labels can protect their intellectual property rights and secure market share. As a manufacturer in China with 20 years of rich experience in die-casting zinc alloy and aluminum alloy bottle caps, this article will provide you with detailed guidance on how to customize bottle caps with anti-counterfeiting labels from multiple aspects such as the types of anti-counterfeiting bottle caps, material selection, design points, and supplier selection.

Bayonet design is a widely used anti-counterfeiting label method. Usually, a specific bayonet structure is carefully set on the bottle cap and bottleneck, making it extremely difficult to open the bottle cap easily after it is tightened.Its function is that this kind of cap structure can effectively prevent illegal opening. Once the bottle cap is opened in an incorrect way, the bayonet may deform or be damaged. In this way, purchasers and relevant personnel can easily judge whether the product has been opened by observing the state of the bottle cap opening.In terms of advantages, this kind of bottle cap structure has high safety and strong durability, and can maintain good anti-counterfeiting performance during transportation and storage.

|

|

Setting a disposable pull ring or tear strip on the edge of the bottle cap is also a very common anti-counterfeiting label method.Its functions are mainly two points: one is to clearly indicate the opening state, and the other is to prevent secondary use. Once the wine bottle cap is opened, the pull ring or tear strip will be damaged and cannot be restored to its original state, thus clearly showing that the product has been opened. At the same time, this can also effectively prevent the bottle cap from being used a second time and reduce the risk of counterfeit products.Its advantage lies in its intuitive and easy-to-understand design. Consumers can easily identify the opening state of the product. Moreover, this design has a low cost and is very suitable for large-scale application.

|  |

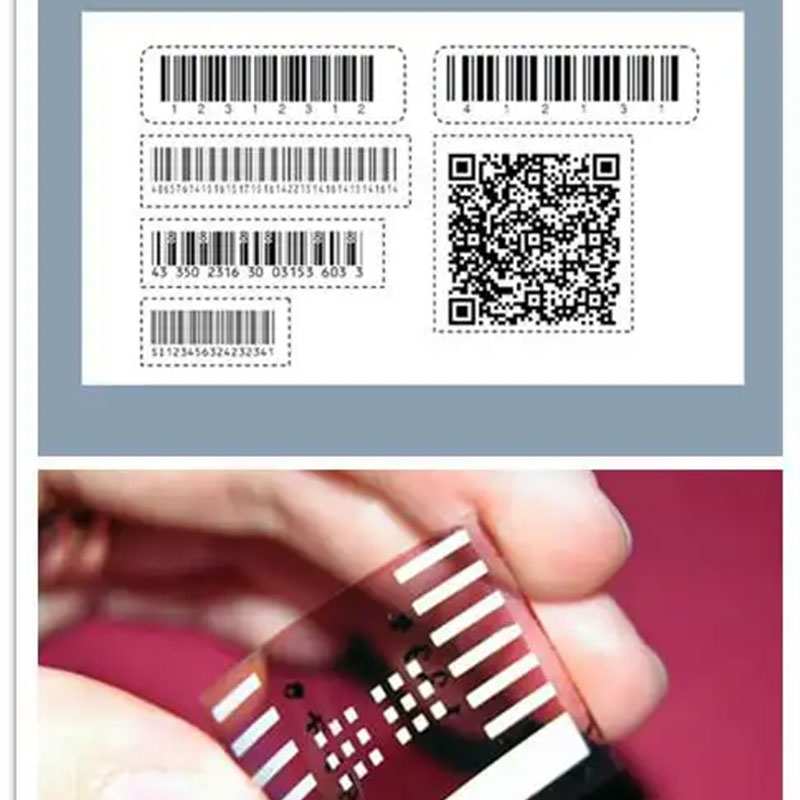

Electronic label technology is increasingly used in anti-counterfeiting labels. Common electronic labels include RFID (radio frequency identification) tags and the like.The role of electronic labels is mainly reflected in two aspects: on the one hand, it can record product information, such as production batch, circulation channel, etc., so as to realize the whole-process tracking and management of products; on the other hand, through special reading equipment, the authenticity and opening state of products can be quickly identified, greatly improving the detection efficiency.The advantage is that electronic labels give people a more professional and standardized feeling and can effectively enhance the brand image. It is more accurate in distinguishing authenticity and greatly reduces the possibility of misjudgment.

|  |

When customizing bottle caps with anti-counterfeiting labels, choosing the right bottle cap material is extremely important. Using zinc alloy or aluminum alloy materials to die-cast bottle caps is a very good choice.Here are some advantages.

Alloy materials can endow the bottle cap with sufficient hardness and strength, enabling it to withstand a certain degree of external impact and torsion. When designing complex anti-counterfeiting structures such as multi-tooth bayonets, the strength of the material can ensure that the bayonet will not deform or be damaged during normal use and possible illegal opening attempts. In this way, even if someone tries to open the bottle cap by force, it will be difficult to succeed due to the strength of the material, thus effectively playing an anti-counterfeiting role.

|

|

Making bottle caps with anti-counterfeiting labels usually requires high-precision mold manufacturing and die-casting processes. Alloy materials can better adapt to this requirement for high-precision processing. For example, zinc-aluminum alloy has good fluidity and castability, and can perfectly fill complex mold shapes during the die-casting process to ensure the dimensional accuracy and consistency of anti-counterfeiting labels. High-precision processing can make the anti-counterfeiting structure more reliable.

|

During storage and transportation, alcoholic beverages may experience various environmental conditions such as temperature changes, humidity changes, and vibrations. Bottle caps made of zinc-aluminum alloy materials can maintain stable performance under these conditions and will not be deformed, corroded, or damaged due to environmental factors. For bottle caps with anti-counterfeiting labels, durability and stability are particularly important because once the bottle cap has a problem, the anti-counterfeiting function is likely to be affected and even the safety of the product may be threatened.

Zinc-aluminum alloy bottle caps look more refined and high-end, perfectly matching the quality of alcoholic beverages. It can not only protect the safety of products but also enhance consumers' trust and recognition of the brand, thereby enhancing the brand's market competitiveness.

|

|

First, check the manufacturer's business qualification certificates and evaluate its experience in the industry. Manufacturers that are compliant, legal, and experienced usually have a deeper understanding of industry standards, technological trends, and customer needs and can provide more professional solutions. They often have more advantages in handling complex anti-counterfeiting designs, dealing with different material requirements, and solving various problems in the production process. Taking our company, Worldbound Precision Metal Products Co., Ltd. as an example, we have obtained international certificates such as ISO 9001 and have 20 years of experience in die-casting bottle caps. We specialize in manufacturing zinc-aluminum alloy die-cast bottle caps. With over a hundred cooperation cases, our product quality is widely praised.

|

Inspect whether the manufacturer's production equipment is advanced and complete. Understand the strength of the manufacturer's technical team, including the number and qualifications of engineers, designers, and technical workers. At the same time, pay attention to whether the manufacturer has a perfect quality control system. Taking our company as an example, we can provide one-stop services for customers including mold opening, die-casting, polishing, surface treatment, product assembly, and shipping. We have automated lathes, fully automatic polishing machines, zinc-aluminum alloy die-casting machines, and CNC equipment. We can make high-precision die-casting molds and realize complex anti-counterfeiting structure designs. Automated production lines can improve production speed and product consistency. We also have a strong technical team and after-sales service, can carry out customized design according to customer needs, provide innovative anti-counterfeiting solutions, and ensure that technical problems in the production process are solved in a timely manner. In addition, we also have a perfect quality control system, including raw material inspection, production process monitoring, and finished product inspection.

|

If you are planning to customize a batch of bottle caps with anti-counterfeiting labels, you can click the quotation button and submit your demand information. Our professionals will contact you for quotation. Come and send an inquiry!

Copyright © 2023 :Worldbound Precision Metal Products Co.,LTD