In the field of perfume production, although perfume caps seem small, they play a crucial role. And before mass-producing perfume caps, making high-quality and precise molds is a key link.

The mold can replicate the shape and size of the perfume cap with extremely high precision, making the cap fit perfectly with the bottle body, effectively preventing leakage and greatly enhancing the overall texture of the product.

It can perfectly reproduce complex design elements such as carvings and reliefs on perfume caps, and also achieve special surface treatment effects, adding value and attractiveness to the product.

Through molds, the same specification perfume caps can be produced in large quantities quickly, greatly improving production efficiency. At the same time, it ensures the consistency of product quality and meets the requirements of modern industrial production.

Different materials of perfume lids require different types of molds to achieve production. When choosing, factors such as product design requirements, cost, and production efficiency should be comprehensively considered to ensure the production of high-quality perfume caps.

Plastic perfume caps have relatively low cost and light weight, and can be mass-produced through injection molds. The price of simple-structured injection molds is generally between 20,000 and 30,000 yuan. If the structure is complex, there are special requirements, or multi-cavity design is used to improve production efficiency, the price may be between 30,000 and 50,000 yuan or even higher.

Glass perfume caps have high transparency, good texture, and are corrosion-resistant, but they are fragile and need to be used and packaged carefully. Blow molding molds can be used to produce hollow glass perfume caps. The price of simple blow molding molds is about 5,000 to 10,000 yuan. The price of complex blow molding molds is between 10,000 and 20,000 yuan. Compression molds can be used to produce solid glass perfume caps. The price is relatively high, generally between 20,000 and 50,000 yuan. For compression molds with special shapes or high-precision requirements, the price may be higher.

Wooden perfume caps are environmentally friendly and have unique texture and texture, but they are not waterproof and manual carving is not efficient. Wooden perfume caps generally do not require molds and are carved out by machines or by hand. The price difference is large, ranging from several hundred yuan to several thousand yuan.

(1) Zinc alloy

Zinc alloy perfume caps have high strength, moderate hardness, can withstand certain pressure and impact, have good casting performance, can make complex shapes and fine details, and the surface can be electroplated, sprayed and other treatments to increase beauty and corrosion resistance. Mass production is carried out by using die-casting molds. This kind of mold can withstand the high-temperature and high-pressure die-casting process and realize more surface textures and decorative effects. The price of ordinary zinc alloy die-casting molds is about 15,000 to 30,000 yuan. If the mold structure is complex, the precision requirements are high, there are special surface treatments or more core-pulling structures, the price may exceed 50,000 yuan.

(2) Aluminum alloy

Aluminum alloy perfume caps are light in weight and high in strength. They are suitable for surface treatments such as anodizing and can create a beautiful appearance and enhance the product grade. The same die-casting mold is used for mass production. The price of its die-casting mold is similar to that of zinc alloy. The ordinary one is between 15,000 and 30,000 yuan. The complex one may be higher. The specific price is affected by factors such as mold size, structural complexity, and production batch.

In conclusion, if you plan to make high-end and exquisite zinc alloy or aluminum alloy caps, die-casting molds can be used for mass production.

Taking our Worldbound Precision Metal Products Co., Ltd.as an example, We are Perfume Bottle Cap Manufacturers. We specialize in producing perfume caps made of zinc alloy and aluminum alloy, as well as manufacturing die-casting molds for perfume caps.

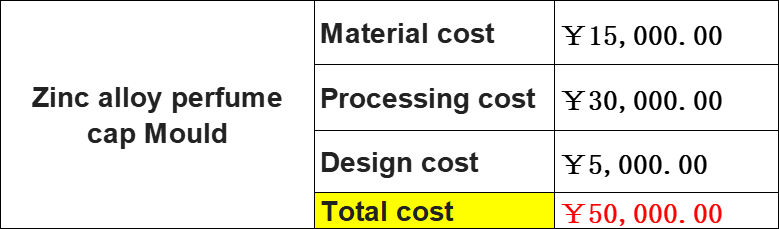

(1) Material cost:

To produce this cap, a high-precision die-casting mold is required. High-quality H13 hot work die steel is selected to ensure sufficient strength and wear resistance in the high-temperature and high-pressure die-casting environment. The material cost is about 15,000 yuan.

(2) Processing cost:

Advanced CNC processing equipment and electric spark processing technology are used to ensure the precision and surface quality of the mold. The processing time is up to one month, and the processing cost is about 30,000 yuan.

(3) Design cost:

Completed by a professional mold design team. After multiple optimizations and simulation analyses, the feasibility and stability of the mold are ensured. The design cost is about 5,000 yuan.

In summary, the total cost of this zinc alloy perfume cap mold is about 50,000 yuan.

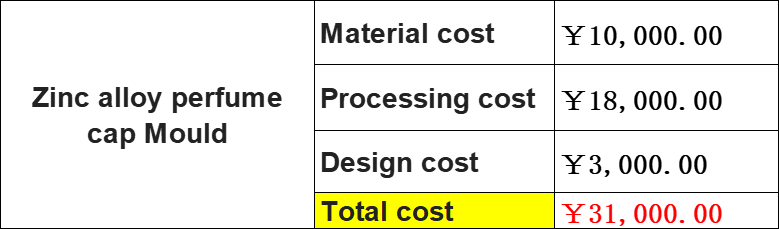

(1) Material cost:

Select hot work die steel suitable for aluminum alloy die casting. The material cost is about 10,000 yuan.

(2) Processing cost:

Use CNC processing equipment and electric spark processing technology. The processing time is about two weeks, and the processing cost is about 18,000 yuan.

(3) Design cost:

Completed by a professional design team. Considering factors such as the fluidity and shrinkage rate of aluminum alloy, optimized design is carried out. The design cost is about 3,000 yuan.

In summary, the total cost of this aluminum alloy perfume cap mold is about 31,000 yuan.

In short, the cost of metal perfume cap molds is relatively high, depending on factors such as mold materials, processing technology, and design requirements. When making perfume caps of different materials, product positioning should be fully considered, and factors such as price, quality, and delivery time should be comprehensively considered to ensure the production of perfume caps that meet the market positioning.

If you are considering making perfume caps made of zinc alloy or aluminum alloy by die casting, you can click the inquiry button and we will tailor a solution for you.

Copyright © 2023 :Worldbound Precision Metal Products Co.,LTD